OURSERVICES

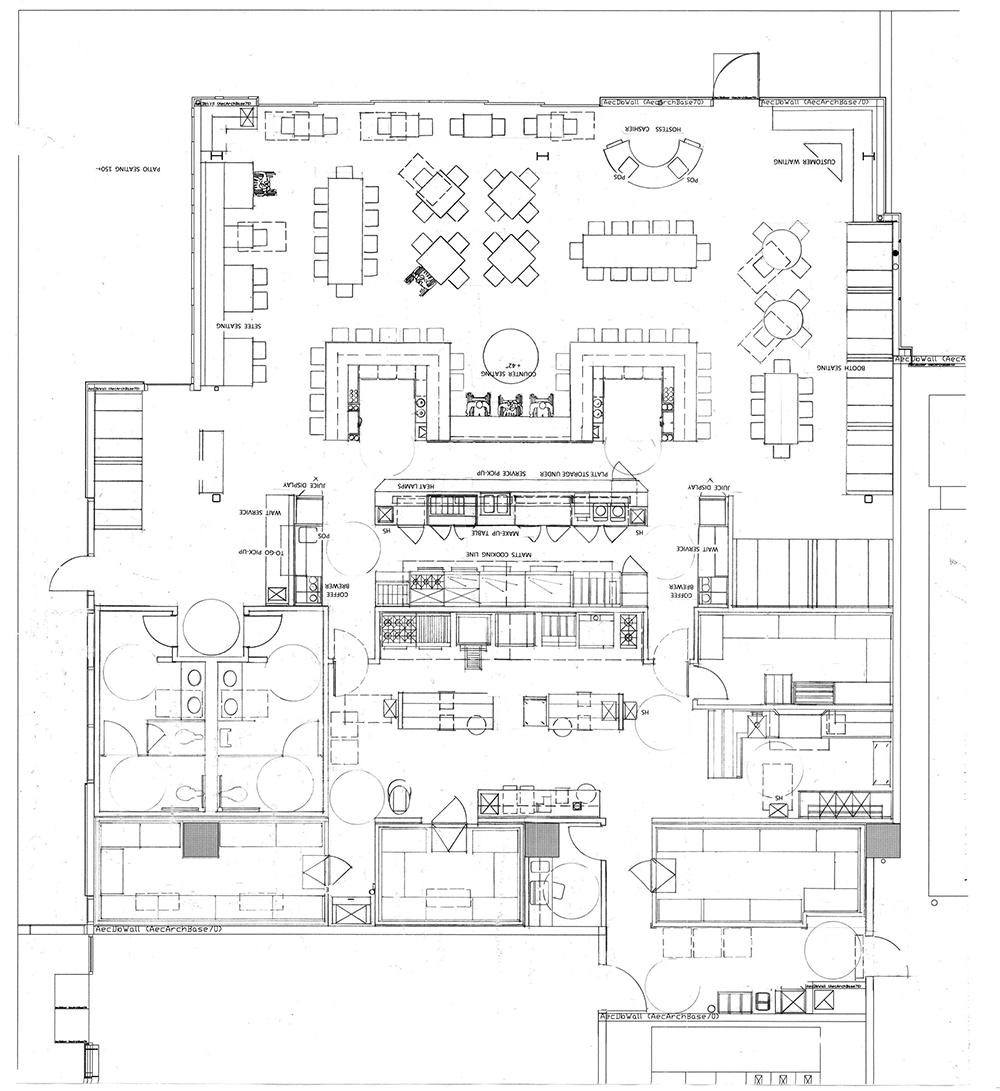

SCHEMATIC DESIGN

Upon project kick off, KEAGGY will start the design process with schematic planning. Schematic drawings will establish the food service equipment locations, identify key areas in the operation, account for all architectural surroundings and show culinary flow based on the overall foodservice operational program.

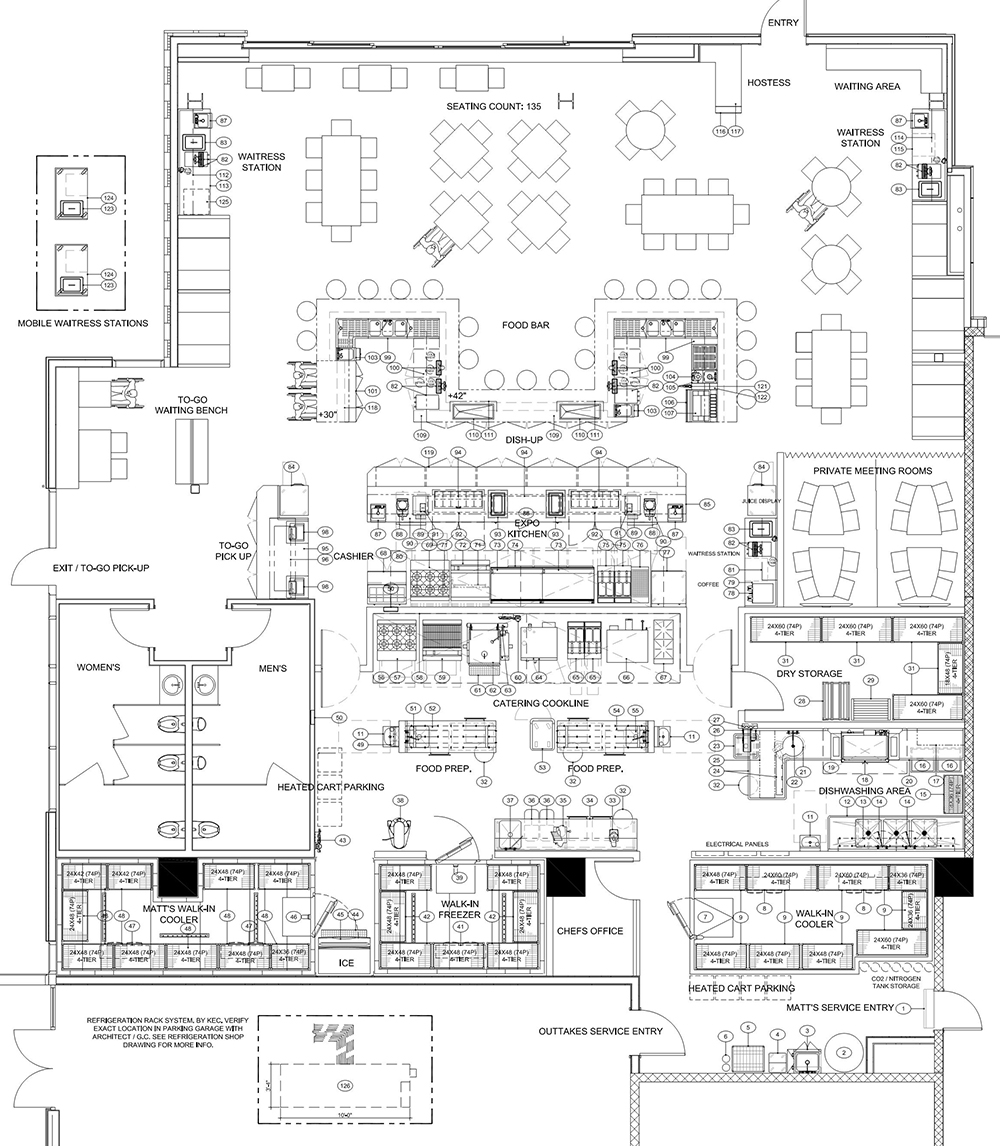

DESIGN DEVELOPMENT

Upon client sign off of the schematic design phase, the design development phase will begin. Electrical, plumbing and mechanical information will be scheduled for the design team’s coordination effort. This phase may also include the addition of manufacturer shop drawings for all the major systems within the project.

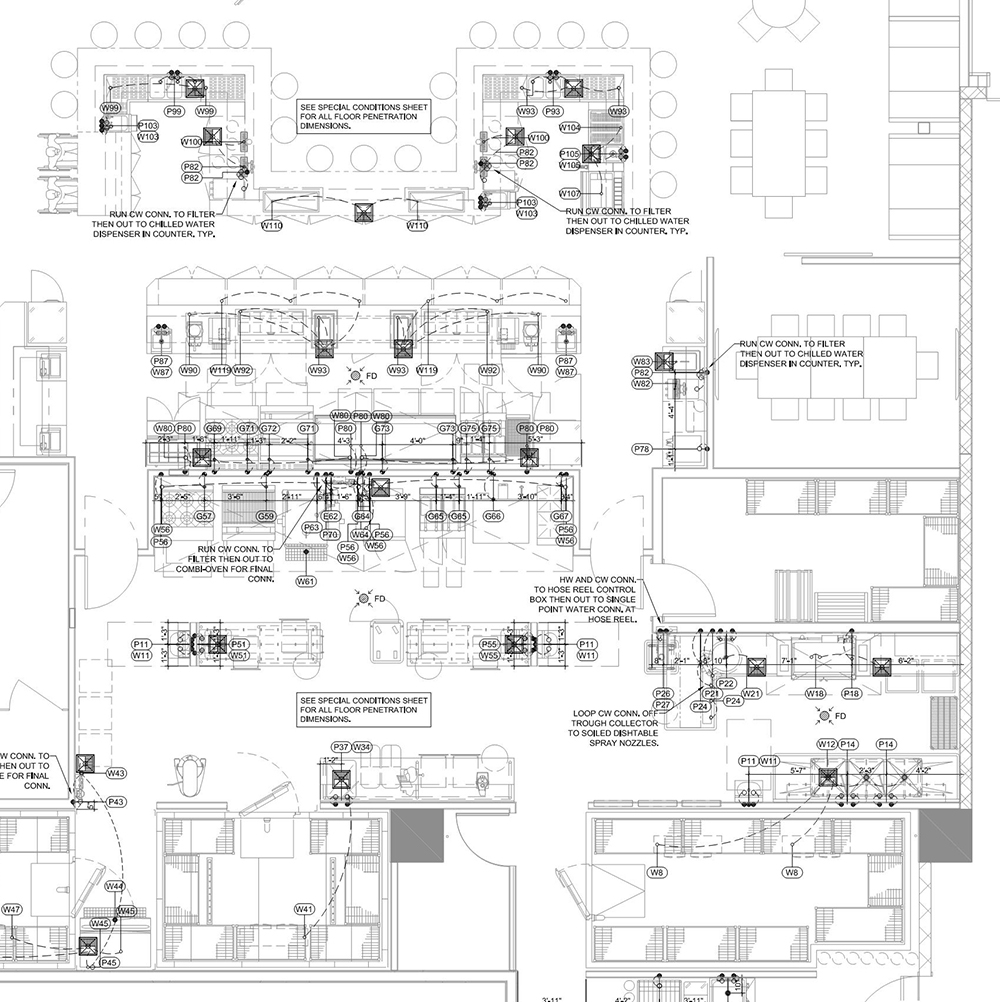

CONSTRUCTION DOCUMENTS

Upon conclusion of the Design Development phase, KEAGGY will start the process of the construction document phase. In this phase the rough-ins for each piece of equipment will be shown on the mechanical, electrical and plumbing rough-in drawings. Job specific standard details will be added along with elevations, sections, and fabrication details.